S235J0 to S235JR metal are two forms of structural metal which are primarily utilized in constructing building and civil engineering. Each of those metal grades are a part of the EN 10025-2 normal, which is a set of structural metal specs that cowl scorching rolled merchandise used for structural functions.

The primary distinction between S235J0 and S235JR metal is that S235J0 isn’t supposed to be used in structural functions whereas S235JR is. It’s because S235J0 isn’t readily formable and doesn’t have good weldability properties. Alternatively, S235JR is appropriate for structural functions and is quickly formable and weldable.

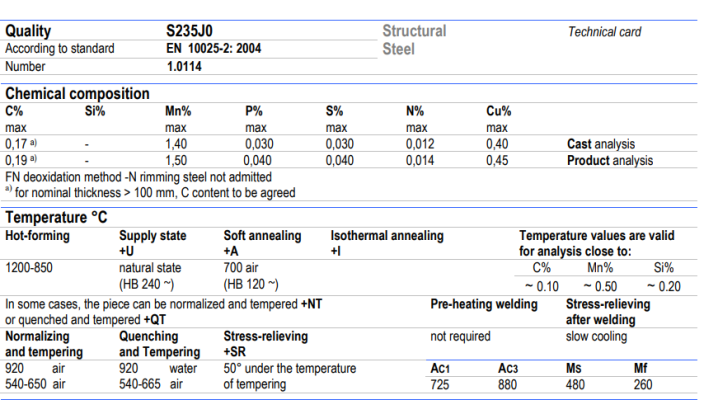

When it comes to chemical composition, S235J0 and S235JR metal are each composed of iron, carbon, and different parts. Nevertheless, the precise chemical composition of every grade varies barely. For instance, S235J0 incorporates a barely greater quantity of carbon than S235JR. Moreover, S235J0 incorporates a better quantity of manganese than S235JR.

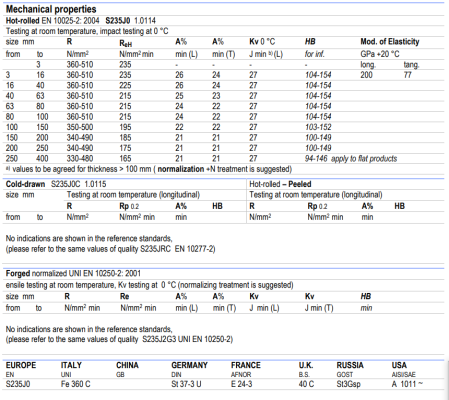

When it comes to mechanical properties, S235J0 and S235JR metal have comparable yield power and tensile power values. Nevertheless, S235J0 has a barely decrease elongation worth than S235JR. This is because of the truth that S235J0 isn’t supposed to be used in structural functions and isn’t readily formable.

General, S235J0 and S235JR metal are two forms of structural metal which are primarily utilized in constructing building and civil engineering. The primary distinction between them is that S235J0 isn’t supposed to be used in structural functions whereas S235JR is. Moreover, S235J0 and S235JR metal have barely totally different chemical compositions and mechanical properties.

S235J0 and S235JR metal are two forms of structural metal which are primarily utilized in constructing and building functions. Each of those steels are a part of the European normal for structural steels, EN 10025.

S235J0 is a low carbon, excessive tensile power structural metal which may be readily welded to different weldable metal. With its low carbon equal, it possesses good cold-forming properties. The plate is produced by totally killed metal course of and provided in normalized or managed rolling situation. S235J0 has a specified minimal yield power of 275 N/mm2 and a specified minimal tensile power of 410 N/mm2.

S235JR is a scorching rolled, low carbon, excessive tensile power structural metal. It may be readily welded to different weldable metal. With its low carbon equal, it possesses good cold-forming properties. The plate is produced by totally killed metal course of and provided in normalized or managed rolling situation. S235JR has a specified minimal yield power of 225 N/mm2 and a specified minimal tensile power of 360 N/mm2.

Each S235J0 and S235JR metal are generally used within the building of buildings and different constructions. They’re additionally used within the manufacture of components for industrial equipment, equivalent to conveyor belts, cranes, and excavators. The steels are additionally used within the manufacturing of bridges, ships, and railway wagons. As well as, they’re used within the manufacturing of strain vessels and storage tanks.

Metal is a extensively used materials within the building business, and it’s usually used within the type of structural metal. Two of essentially the most generally used forms of structural metal are S235J0 and S235JR. Though these two forms of metal are comparable in some ways, there are some key variations between them that may have an effect on their value. This text will discover the associated fee variations between S235J0 and S235JR metal.

S235J0 to S235JR metal are each carbon steels which are generally used within the building business. They’re each non-alloy structural steels, which implies that they’re designed for structural functions moderately than for mechanical or aesthetic functions. The primary distinction between the 2 forms of metal is of their chemical composition. S235J0 incorporates a better stage of carbon than S235JR, which supplies it a better power and hardness. This makes S235J0 dearer than S235JR.

The price of S235J0 and S235JR metal additionally is dependent upon the scale and form of the fabric. S235J0 is usually dearer than S235JR in relation to bigger shapes and sizes, because it requires extra materials to provide. Alternatively, S235JR is normally cheaper than S235J0 in relation to smaller shapes and sizes, because it requires much less materials to provide.

Along with the associated fee variations between S235J0 to S235JR metal, there are additionally variations of their mechanical properties. S235J0 has a better yield power than S235JR, which makes it extra appropriate for functions that require excessive power. S235JR, alternatively, has a better ductility than S235J0, which makes it extra appropriate for functions that require flexibility.

In conclusion, S235J0 and S235JR metal are each generally used within the building business. Nevertheless, there are some key variations between them that may have an effect on their value. S235J0 is usually dearer than S235JR attributable to its greater carbon content material, and additionally it is dearer for bigger shapes and sizes. S235JR is normally cheaper than S235J0 for smaller shapes and sizes. Moreover, S235J0 has a better yield power than S235JR, whereas S235JR has a better ductility than S235J0.

The chemical composition of S235J0 and S235JR metal are very comparable, as they each include the identical quantity of carbon, silicon, manganese, phosphorus, and sulfur. Nevertheless, there are some slight variations between the 2 grades.

S235J0 incorporates a barely greater quantity of chromium than S235JR, with 0.17% chromium in comparison with 0.16%. This distinction is because of the truth that S235J0 is a structural metal grade, whereas S235JR is a structural metal grade with improved yield power.

The chemical composition of S235J0 and S235JR metal additionally differ when it comes to their sulfur content material. S235J0 incorporates 0.05% sulfur, whereas S235JR incorporates 0.035% sulfur. This distinction is because of the truth that S235J0 is a structural metal grade, whereas S235JR is a structural metal grade with improved yield power.

As well as, S235J0 incorporates a barely greater quantity of manganese than S235JR, with 1.50% manganese in comparison with 1.40%. This distinction is because of the truth that S235J0 is a structural metal grade, whereas S235JR is a structural metal grade with improved yield power.

General, the chemical composition of S235J0 and S235JR metal are very comparable, with solely slight variations of their chromium, sulfur, and manganese content material. Each grades are appropriate to be used in structural functions, with S235JR being the popular grade for functions that require improved yield power.

The mechanical properties of metal are important for its use in quite a lot of functions. Two of essentially the most generally used steels within the building business are S235J0 and S235JR. Each steels are structural steels with a grade of 235, which signifies a yield power of 235 MPa. Whereas the 2 steels are comparable when it comes to their grade, there are some variations of their mechanical properties.

The tensile power of S235J0 is between 360-510 MPa, whereas the tensile power of S235JR is between 370-530 MPa. The elongation of S235J0 is between 17-21%, whereas the elongation of S235JR is between 17-23%. The impression vitality of S235J0 is 27 Joules at -20°C, whereas the impression vitality of S235JR is 27 Joules at -20°C.

The yield power of S235J0 is between 225-275 MPa, whereas the yield power of S235JR is between 215-235 MPa. The Brinell hardness of S235J0 is between 120-170 HB, whereas the Brinell hardness of S235JR is between 130-180 HB. The Charpy impression take a look at of S235J0 is between 27-41 Joules at -20°C, whereas the Charpy impression take a look at of S235JR is between 27-40 Joules at -20°C.

In conclusion, whereas each S235J0 and S235JR are structural steels with a grade of 235, there are some variations of their mechanical properties. The tensile power, elongation, impression vitality, yield power, Brinell hardness, and Charpy impression take a look at of S235J0 are barely greater than these of S235JR.