“Unlock the Energy of C12 metal grade: Uncover Its Chemical Properties, Composition, and Mechanical Equivalents!”

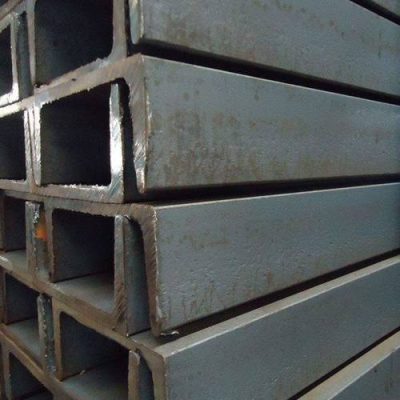

C12 metal grade is a low-alloy metal that’s generally used within the building of commercial and industrial constructions. It’s composed of a mix of iron and carbon, and is understood for its energy and sturdiness. This metal grade can be extremely proof against corrosion and has glorious weldability.

The chemical composition of C12 metal grade is as follows: Carbon (C) 0.12-0.20%, Manganese (Mn) 0.30-0.60%, Phosphorus (P) 0.040%, Sulfur (S) 0.040%, Silicon (Si) 0.15-0.30%, Chromium (Cr) 0.40-0.60%, Nickel (Ni) 0.30-0.50%, Molybdenum (Mo) 0.15-0.25%, and Vanadium (V) 0.08-0.15%.

The mechanical properties of C12 metal grade are as follows: Tensile Energy (MPa) ≥520, Yield Energy (MPa) ≥340, Elongation (%) ≥17, Hardness (HB) ≤187, and Affect Worth (J) ≥27.

The bodily properties of C12 metal grade are as follows: Density (g/cm3) 7.85, Melting Level (°C) 1420-1460, Thermal Conductivity (W/mK) 45.7, Particular Warmth (J/kgK) 0.48, and Electrical Resistivity (μΩm) 0.14.

C12 metal grade is a flexible materials that can be utilized in a wide range of functions. It’s extremely proof against corrosion and has glorious weldability, making it ultimate to be used within the building of commercial and industrial constructions. Its mechanical properties make it appropriate to be used in functions that require energy and sturdiness. Moreover, its bodily properties make it appropriate to be used in functions that require thermal and electrical conductivity.

C12 metal grade is a low-alloy carbon metal that’s generally used within the manufacturing of assorted industrial parts. It’s composed of a mix of iron and carbon, with a carbon content material of 0.12-0.20%. The addition of carbon to the iron will increase the energy and hardness of the metal, making it appropriate to be used in a wide range of functions.

C12 metal grade consists of various alloying parts, together with manganese, silicon, phosphorus, sulfur, and chromium. These parts are added to the metal in an effort to enhance its mechanical properties, resembling its energy, toughness, and ductility. The addition of manganese and silicon will increase the metal’s energy and hardness, whereas the addition of phosphorus and sulfur will increase its machinability. The addition of chromium will increase the metal’s corrosion resistance.

C12 metal grade is often used within the manufacturing of parts that require excessive energy and toughness, resembling gears, shafts, and fasteners. It is usually used within the manufacturing of springs, wire ropes, and different parts that require excessive ranges of corrosion resistance.

General, C12 metal grade is a flexible and dependable materials that’s appropriate for a wide range of industrial functions. Its mixture of energy, toughness, and corrosion resistance make it an excellent alternative for a lot of parts.

The mechanical properties of C12 metal grade are necessary for figuring out its suitability for varied functions. This metal grade is a low-carbon metal that’s generally used within the building of bridges, buildings, and different constructions. It is usually used within the manufacture of automotive parts and machine components.

The mechanical properties of C12 metal grade embody its tensile energy, yield energy, and elongation. The tensile energy of C12 metal grade is often between 400 and 500 MPa. This means the metal’s skill to withstand breaking below rigidity. The yield energy of C12 metal grade is often between 250 and 350 MPa. This means the metal’s skill to withstand deformation below load. The elongation of C12 metal grade is often between 20 and 30%. This means the metal’s skill to stretch earlier than breaking.

Along with these mechanical properties, C12 metal grade additionally has good weldability and machinability. It may be welded utilizing typical welding methods and may be machined utilizing commonplace machine instruments.

General, C12 metal grade is a flexible materials that’s appropriate for a variety of functions. Its mechanical properties make it an excellent alternative for structural functions, whereas its weldability and machinability make it appropriate to be used within the manufacture of automotive parts and machine components.

The C12 metal grade is a structural metal grade that’s extensively used within the building trade. It’s a low-carbon metal grade that’s extremely ductile and has glorious weldability properties. It is usually identified for its good machinability and formability properties. The C12 metal grade is equal to the next grades: ASTM A576, ASTM A29, SAE J403, SAE J412, SAE J414, and DIN 17222. All of those grades have related mechanical properties and are appropriate to be used within the building trade. The C12 metal grade can be equal to the next grades: BS 970 080M15, BS 970 070M20, BS 970 080M30, BS 970 080M40, and BS 970 080M50. These grades are all low-carbon metal grades which can be extremely ductile and have glorious weldability properties. They’re additionally identified for his or her good machinability and formability properties.

C12 metal grade is a low-alloy metal that’s generally used within the manufacturing trade. It’s a versatile materials that provides a spread of advantages, together with glorious weldability, good machinability, and excessive energy. This text will study the benefits of utilizing C12 metal grade in manufacturing.

One of many major advantages of C12 metal grade is its weldability. This metal grade has a low carbon content material, which makes it simpler to weld than different metal grades. It additionally has a low sulfur content material, which helps to cut back the chance of weld defects. Moreover, C12 metal grade has a excessive tensile energy, which makes it appropriate to be used in functions that require sturdy welds.

One other benefit of C12 metal grade is its machinability. This metal grade has a low carbon content material, which makes it simpler to machine than different metal grades. It additionally has a low sulfur content material, which helps to cut back the chance of software put on. Moreover, C12 metal grade has a excessive hardness, which makes it appropriate to be used in functions that require exact machining.

Lastly, C12 metal grade has a excessive strength-to-weight ratio. Which means it’s light-weight but sturdy, making it appropriate to be used in functions that require a powerful but light-weight materials. Moreover, C12 metal grade has a excessive fatigue energy, which makes it appropriate to be used in functions that require parts that may face up to repeated stress.

In conclusion, C12 metal grade is a flexible materials that provides a spread of advantages, together with glorious weldability, good machinability, and excessive energy. It’s appropriate to be used in a wide range of functions, together with people who require sturdy welds, exact machining, and light-weight but sturdy parts.